Upgrade Your Finishing Machinery Today!

Solidly constructed for long term reliability, Dubois equipment is engineered with innovations to improve productivity and minimize clean-up, maintenance and downtime. It’s manufactured in the U.S., to assure fast response and prompt availability of replacement parts from local suppliers.

Request A Quote Today

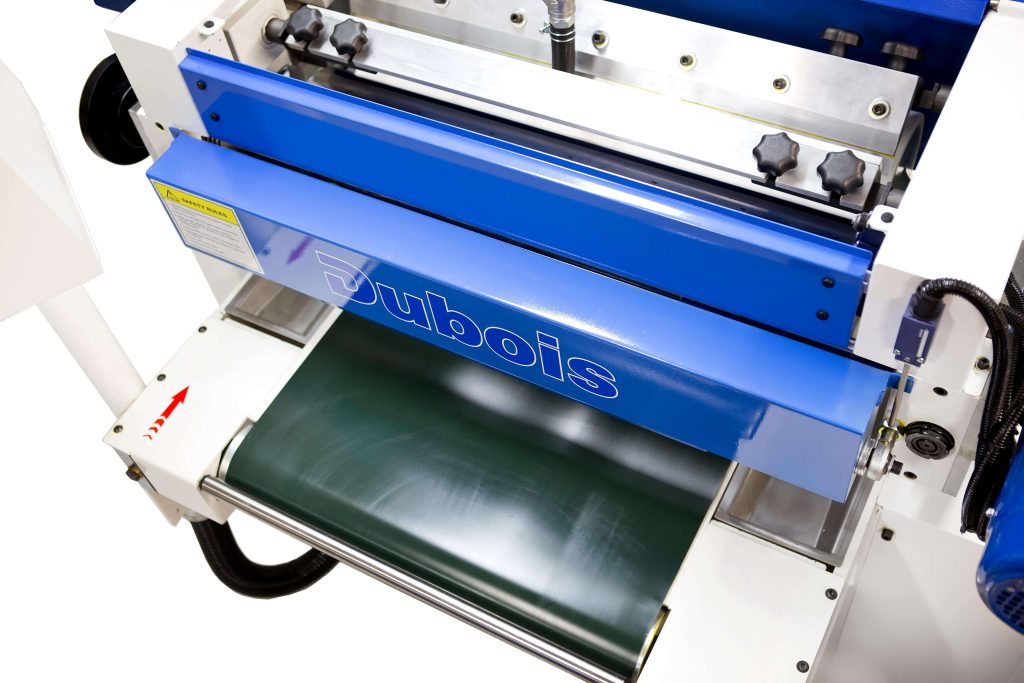

The Dubois Compact Differential Roll Coater provides a precise application of coating to flat substrate in a newly upgraded machine which is sized as a direct replacement for many competitors machines. The compact differential roll coater uses a rubber application roller to apply coating directly to a part passing through the machine; the durometer of these rolls is selected based on the finish being applied. The coating thickness is varied by the speed and direction of the doctor roll. Our Roll Coating machines are capable of handling water based, solvent based, and UV based coatings. Dubois Roll Coaters are designed for easy changeover of materials.