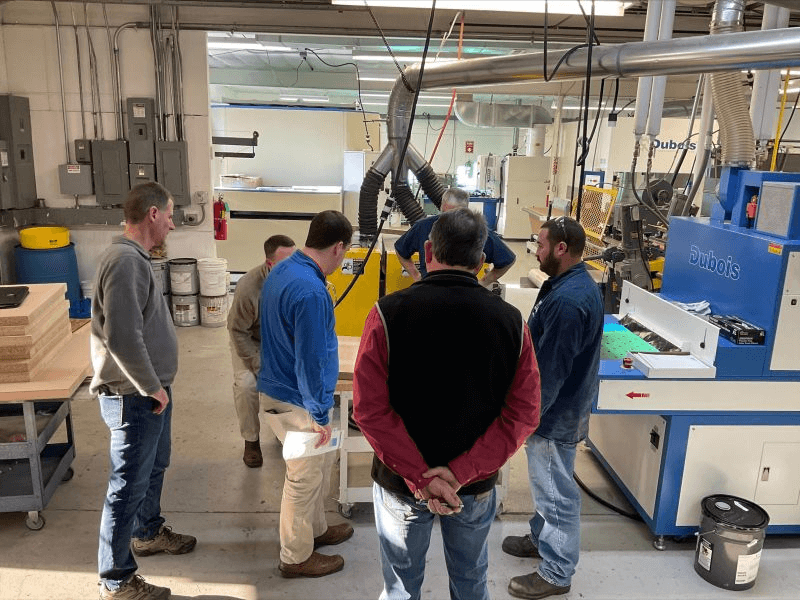

The productivity and profitability of your business depend on the performance of your equipment. When investing in finishing equipment and systems, you need to know you are purchasing a system you can count on, not only for quality and consistency, but long service life.

While other manufacturers may offer similar finishing equipment, one of the key advantages Dubois Equipment offers you is a system that is built with high quality and widely available components. Why is this important? Some systems are developed using parts that are hard to find, or only available from overseas sources. In the event of a simple component failure, your otherwise functional machine sits silently, while you are faced with costly downtime.

Your Dubois system will be built using the highest quality components, for a system that produces flawless finishes, run after run. In the event that a component fails, you will have no problem finding a replacement to get and running again fast. This is how we deliver excellent performance and long service life in our finishing equipment. Many Dubois customers report that their equipment is still running after 40 years of multiple shifts.

Invest in finishing equipment and systems you can depend on. Contact the Dubois team to learn how we can meet your needs.